For 24 V applications, we recommend the 24v12 or 24v23 versions. We strongly recommend against using the 18v7, 18v15, or 18v25 with 24 V batteries, which can significantly exceed 24 V when fully charged and are dangerously close to the maximum voltage limits of these lower-voltage controllers.

|

|

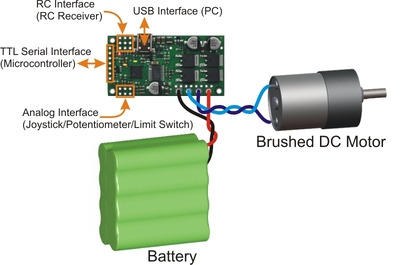

Simple High-Power Motor Controller 18v25 or 24v23 simplified connection diagram. |

|---|

Key Features

- Simple bidirectional control of one DC brush motor.

- 5.5 V to 30 V (18v7, 18v15, and 18v25) or 40 V (24v12 and 24v23) operating supply range.

- 7 A to 25 A maximum continuous current output without a heat sink, depending on controller model

-

Four communication or control options:

- USB interface for direct connection to a PC.

- Logic-level (TTL) serial interface for direct connection to microcontrollers or other embedded controllers.

- Hobby radio control (RC) pulse width interface for direct connection to an RC receiver or RC servo controller.

- 0–3.3 V analog voltage interface for direct connection to potentiometers and analog joysticks.

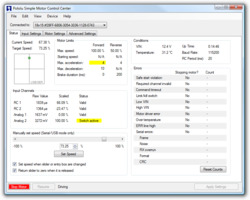

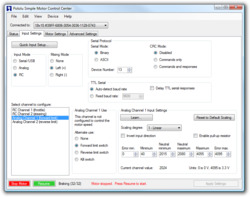

- Simple configuration and calibration over USB with free configuration program (Windows 8, 7, Vista, Windows XP, and Linux compatible).

|

|

Note: A USB A to mini-B cable (not included) is required to connect this controller to a computer.

Additional Features

- Comprehensive user’s guide with plenty of connection diagrams and sample code.

- Adjustable maximum acceleration and deceleration to limit electrical and mechanical stress on the system.

- Adjustable starting speed, maximum speed, and amount of braking when speed is zero.

- Optional safety controls to avoid unexpectedly powering the motor.

- Input calibration (learning) and adjustable scaling degree for analog and RC signals.

- Under-voltage shutoff with hysteresis for use with batteries vulnerable to over-discharging (e.g. LiPo cells).

- Adjustable over-temperature threshold and response.

- Adjustable PWM frequency from 1 kHz to 22 kHz (maximum frequency is ultrasonic, eliminating switching-induced audible motor shaft vibration).

- Error LED linked to a digital ERR output, and connecting the error outputs of multiple controllers together optionally causes all connected controllers to shut down when any one of them experiences an error.

- Field-upgradeable firmware.

-

USB/Serial features:

- Controllable from a computer with native USB, via serial commands sent to the device’s virtual serial (COM) port, or via TTL serial through the device’s RX/TX pins.

- Example code in C#, Visual Basic .NET, and Visual C++ is available in the Pololu USB Software Development Kit

- Optional CRC error detection to eliminate communication errors caused by noise or software faults.

- Optional command timeout (shut off motors if communication ceases).

- Supports automatic baud rate detection from 1200 bps to 500 kbps, or can be configured to run at a fixed baud rate.

- Supports standard compact and Pololu protocols as well as the Scott Edwards Mini SSC protocol and an ASCII protocol for simple serial control from a terminal program.

- Optional serial response delay for communicating with half-duplex controllers such as the Basic Stamp.

- Controllers can be easily chained together and to other Pololu serial motor and servo controllers to control hundreds of motors using a single serial line.

|

|

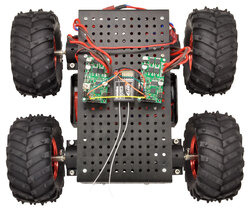

Two Pololu Simple Motor Controllers enable mixed RC-control of Dagu Wild Thumper 4WD all-terrain chassis. |

|---|

-

RC features:

- 1/4 µs pulse measurement resolution.

- Works with RC pulse frequencies from 10 to 333 Hz.

- Configurable parameters for determining what constitutes an acceptable RC signal.

- Two RC channels allow for single-stick (mixed) motor control, making it easy to use two simple motor controllers in tandem on an RC-controlled differential-drive robot (you might find our RC servo Y splitter cables useful for connecting two SMCs to a single RC receiver).

- RC channels can be used in any mode as limit or kill switches (e.g. use an RC receiver to trigger a kill switch on your autonomous robot).

- Battery elimination circuit (BEC) jumper can power the RC receiver with 5 V or 3.3 V.

-

Analog features:

- 0.8 mV (12-bit) measurement resolution.

- Works with 0 to 3.3 V inputs.

- Optional potentiometer/joystick disconnect detection.

- Two analog channels allow for single-stick (mixed) motor control, making it easy to use two simple motor controllers in tandem on a joystick-controlled differential-drive robot.

- Analog channels can be used in any mode as limit or kill switches.

This video demonstrates the versatility of the Simple Motor Controller by showing how it can be controlled directly from the analog output of a Sharp analog distance sensor—there is no intermediate control board and no programming involved. For more information on this example, including the SMC settings file and a list of parts used, see our blog post about the demo.

Simple Motor Controller Comparison Table

The Simple Motor Controllers are available in several input voltage ranges and output current ranges:

18v7 |

18v15 |

24v12 |

18v25 |

24v23 |

|

|---|---|---|---|---|---|

| Absolute max voltage: | 30 V | 30 V | 40 V | 30 V | 40 V |

| Recommended max voltage(1): | 24 V | 24 V | 34 V | 24 V | 34 V |

| Max continuous current w/o heat sink: | 7 A | 15 A | 12 A | 25 A | 23 A |

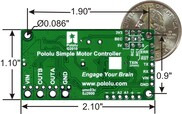

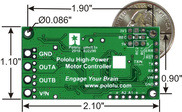

| Width: | 1.1" (2.8 cm) | 1.1" (2.8 cm) | 1.1" (2.8 cm) | 1.2" (3.1 cm) | 1.2" (3.1 cm) |

| Length: | 2.1" (5.3 cm) | 2.1" (5.3 cm) | 2.1" (5.3 cm) | 2.3" (5.8 cm) | 2.3" (5.8 cm) |

| Weight(2): | 7 g | 7 g | 7 g | 12 g | 12 g |

| Available with connectors installed? | Yes | Yes | Yes | No | No |

1 We do not recommend using the 18v7, 18v15, or 18v25 versions with 24 V batteries, which can significantly exceed 24 V when fully charged. The 24v12 and 24v23 are the much more appropriate controller for 24 V applications.

2 This is the weight of the board without header pins, terminal blocks, or through-hole power capacitor.

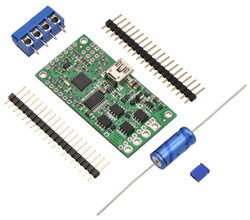

Included Hardware

|

|

Most Simple Motor Controllers are available “fully assembled”, with the power capacitor and connectors pre-installed, or with these components included but not soldered in. For example, a fully assembled 18v15 ships as shown in the left picture above, and an 18v15 with included hardware ships as shown in the right picture above (the included hardware consists of a power capacitor, a 40×1 straight 0.1" male header strip, a 5mm-pitch 4-pin terminal block, and a blue shorting block).

The connector-free version allows flexibility in choice of connectors and placement of the power capacitor (e.g. on the other side of the board) to accommodate compact installations or to make room for a heat sink.

Note: The power capacitor has a significant effect on performance; the included capacitor is the minimum size recommended, and bigger ones can be added if there is space. A bigger capacitor might be required if the power supply is poor or far (more than about a foot) from the controller.

The included terminal blocks are only rated for 16 A, so we recommend soldering thick wires directly to the connector-free version of the board and using higher-current connectors for applications that will exceed the terminal blocks’ ratings.

Dimensions

| Size: | 2.3" x 1.2" x 0.4" |

|---|---|

| Weight: | 12 g1 |

General specifications

| Motor channels: | 1 |

|---|---|

| Control interface: |

USB; non-inverted TTL serial; RC servo pulses; analog voltage2 |

| Minimum operating voltage: | 5.5 V |

| Maximum operating voltage: | 30V/ 40 V |

| Continuous output current per channel: | 7/12/15/23/25 A3 |

| Maximum PWM frequency: | 21.77 kHz |

| Maximum logic voltage: | 3.3 V4 |

| Reverse voltage protection?: | N |

| Partial kit?: | Y |

Notes:

- 1

- Without included hardware.

- 2

- Autodetects baud rates between 1200 and 500,000 bps, or can be set to any fixed baud rate in this range.

- 3

- Typical results at room temperature without a heat sink.

- 4

- All digital inputs are 5V tolerant.

-

Documentation and other information

Pololu Simple Motor Controller User’s Guide (Printable PDF)

Pololu Simple Motor Controller User’s Guide (Printable PDF)

User’s manual for the Pololu Simple Motor Controllers.

Pololu USB Software Development KitThe Pololu USB SDK contains example code for making your own applications that use native USB to control the Jrk Motor Controller, Maestro Servo Controller, Simple Motor Controller, or USB AVR Programmer.

Application Note: Using AutoHotkey with Pololu USB Products (Printable PDF)

Application Note: Using AutoHotkey with Pololu USB Products (Printable PDF)

An application note about using AutoHotkey for Windows to control Pololu USB products.

File downloads

- Simple Motor Controller Windows Drivers and Software (release 121204) (5MB zip)

- This ZIP archive contains the installation files for the Simple Motor Control Center, the Simple Motor Controller command-line utility (SmcCmd), and the required USB drivers for Microsoft Windows.

| Electrical Specifications | |

| Output Current | 7A |

| Minimum Operating Voltage | 5.5V |

| Maximum Operating Voltage | 30V |

| Physical Attributes | |

| Weight | 14g |

| Dimensions | 2.3 x 1.2x 0.4 |

| Additional Information | |

| Warranty | |

Pololu 1372 / 1378 / 1376 Simple Motor Controller 18V7/ 24V12/ 18V15 (Fully Assembled)

- Brand: Pololu

- Product Code: Pololu-Simple-HP-Motor-Control-FA

- Reward Points: 139

- Availability: In Stock

- रo 13,767.00

-

रo 13,323.00

- Price in reward points: 13878

-

- 2 or more रo 13,656.00

- 5 or more रo 13,545.00

- 10 or more रo 13,434.00

Available Options

Related Products

DC Motor 37mm, 12V/ 50RPM

Metal geared DC motor and bracket from Makeblock now available in India! Specification: ..

रo 1,985.00

Stepper Motor- 42BYG

Makeblock 42BYG High quality Step Motor now available in India! The 42BYG step motor can be used..

रo 2,585.00

TowerPro MG-945 Digital High Speed Servo

High-speed yet dead-accurate. A servo with digital control. Specifications: Dimens..

रo 811.00

TowerPro MG-946R Digital High Speed Servo

The premium-end, high speed and super accurate digital servo from the house of TowerPro. ..

रo 776.00

TowerPro MG-995 Digital Metal Gear Servo

High-speed yet dead-accurate. A servo with digital control for precise maneuver. Specifica..

रo 370.00

TowerPro MG-996R Digital Metal Gear Servo

The premium-end, high speed and super accurate digital servo from the house of TowerPro. ..

रo 630.00 रo 850.00

Stepper Motor Bracket 42BYG

42BYG Stepper Motor Bracket from Makeblock Made from 6061 aluminum extrusion , 3mm thick, an..

रo 885.00

DC Motor 32mm, 12V/ 10RPM

DC motors can be defined as an extension of DC motor which already had its Insight details demystifi..

रo 172.00

Pololu 2995 G2 High-Power Motor Driver 24v21

This discrete MOSFET H-bridge motor driver enables bidirectional control of one high-power DC brushe..

रo 3,787.00 रo 3,945.00

Pololu 3142 / 3143 / 3146 / 3147 / 3148 / 3149 Jrk USB Motor Controller with Feedback

This compact motor controller makes closed-loop speed or position (but not both!) control of a brush..

रo 3,976.00 रo 4,141.00

Pololu 5035/5034/5033 Motoron M3H256 Triple Motor Controller for Raspberry Pi

The Motoron M3H256 Triple Motor Controller makes it easy to control DC motors from a Raspberry Pi (M..

रo 3,226.00 रo 3,360.00

Pololu 2993 H2 High-Power Motor Driver 36v11 CS

This discrete MOSFET H-bridge motor driver enables bidirectional control of one high-power DC brushe..

रo 4,532.00 रo 4,721.00

Tags: Pololu, Simple, High-Power, Motor, Controller,