This is the large version of a simple carrier for Allegro’s ACS37220LEZATR-150B3/150B5 Hall effect-based, electrically isolated current sensor, which offers an extra-low-resistance (~0.1 mΩ) current path, a high 150 kHz bandwidth for fast response times, and an overcurrent fault output with a user-configurable threshold.

We are offering these breakout boards with support from Allegro Microsystems as an easy way to use or evaluate their ACS37220 Hall effect-based, electrically isolated current sensors with user-configurable overcurrent fault output; we therefore recommend careful reading of the ACS37220 datasheet before using this product. The following list details some of the sensor’s key features:

- Hall effect-based sensor with electrically isolated current path allows the sensor to be inserted anywhere along the current path and to be used in applications that require electrical isolation.

- Extra-low IC primary current path resistance of 0.1 mΩ for higher efficiency.

- Differential Hall sensing rejects common-mode fields, so the orientation of the sensor relative to uniform external magnetic fields (e.g. the Earth’s magnetic field) has less effect on the measurement.

- High-bandwidth 150 kHz analog output voltage proportional to AC or DC currents.

- Less than 4 µs response time.

- Output is not ratiometric (i.e. the zero point and sensitivity are independent of the actual supply voltage), which provides immunity from noisy supplies.

- User-configurable overcurrent fault output with 3 µs response time indicates when the current magnitude exceeds the set threshold and can be used for fast short-circuit detection.

- Integrated digital temperature compensation circuitry allows improved accuracy over the full operating temperature range.

- Automotive-grade operating temperature range of -40°C to 150°C.

- Carrier boards, available in compact and large sizes, offer a variety of ways to insert it into the current path and 0.1″-pitch (breadboard compatible) power, ground, and output pins.

- The PCB is made with 2-layer (compact versions) or 6-layer (large versions) 2-oz copper, so very little power is lost in the module.

- 3.3V and 5V versions available.

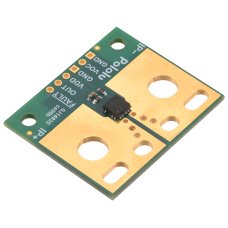

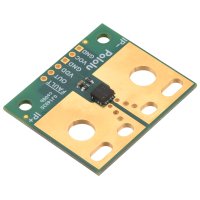

The connection points are labeled on the silkscreen, which is on the bottom side of the compact versions and on both sides of the large versions. The bottom silkscreen also shows the direction that is interpreted as positive current flow via the +i arrow.

Details for item #5296

- Typical operating voltage: 3.3 V

- Current sense: 8.8 mV/A

- Minimum logic voltage: 3.15 V

- Maximum logic voltage: 3.45 V

- Supply current: 16 mA1

- Version: -150A to +150A (bidirectional 150A), 3.3V

- Current sensor: Allegro ACS37220LEZATR-150B3

This large carrier features the ACS37220LEZATR-150B3, which is intended for nominal 3.3 V operation and is designed for bidirectional input current from -150 A to +150 A. This version can be visually distinguished from the other versions by the “3V3 B15” printed on the bottom side, as shown in the left picture above.

A compact carrier is also available for this sensor IC for more space-constrained applications or to evaluate the IC’s performance with a smaller PCB area and fewer copper layers for thermal dissipation.

Using the sensor

This sensor has five required connections: the input current (IP+ and IP-), logic power (VDD and GND), and the sensor output (VOUT).

The sensor requires a supply voltage of 3.15 V to 3.45 V to be connected across the VDD and GND pads, which are labeled on the bottom silkscreen. The sensor outputs an analog voltage on VOUT that is centered at 1.65 V and changes by 8.8 mV per amp of input current, with positive current increasing the output voltage and negative current decreasing the output voltage:

- VOUT=1.65V+0.0088VA⋅IP

- IP=VOUT–1.65V0.0088VA=(VOUT–1.65V)⋅114AV

The output is not ratiometric, so the zero point and sensitivity are independent of the actual supply voltage.

Setting the overcurrent fault threshold

The optional VOC pin can be used to set the overcurrent fault threshold. An on-board 130 kΩ resistor between VOC and GND sets the default overcurrent fault threshold to approximately 200% of the nominal sensing range, and an external resistor can be added in parallel between VOC and GND to lower this threshold to between 50% and 200%. The following equation gives the value of this parallel resistor, ROC, in kΩ as a function of overcurrent fault threshold percentage P:

- ROC=130kΩ⋅P197%–P

So for example, to set the overcurrent fault limit to 50% of the nominal sensing range, a 44 kΩ external resistor can be added between VOC and GND:

- ROC=130kΩ⋅50%197%–50%≈44kΩ

As a shortcut, VOC can be connected directly to ground to set the overcurrent fault limit to 100% of the nominal sensing range.

Alternatively, the on-board resistor can be replaced, or a low-impedance voltage source can be applied directly to the VOC pin as described in the ACS37220 datasheet.

The optional FAULT pin is normally at VDD and is pulled low when the IP current magnitude exceeds the set overcurrent fault threshold in either direction. This pin only asserts while the fault condition is present (it is not latched).

We manufacture these boards in-house at our Las Vegas facility, which gives us the flexibility to make these current sensors with custom default overcurrent fault thresholds. If you are interested in customization, please contact us.

Details for item #5298

- Typical operating voltage: 5 V

- Current sense: 13.3 mV/A

- Minimum logic voltage: 4.5 V

- Maximum logic voltage: 5.5 V

- Supply current: 16 mA1

- Version: -150A to +150A (bidirectional 150A), 5V

- Current sensor: Allegro ACS37220LEZATR-150B5

This large carrier features the ACS37220LEZATR-150B5, which is intended for nominal 5 V operation and is designed for bidirectional input current from -150 A to +150 A. This version can be visually distinguished from the other versions by the “5V B15” printed on the bottom side, as shown in the left picture above.

A compact carrier is also available for this sensor IC for more space-constrained applications or to evaluate the IC’s performance with a smaller PCB area and fewer copper layers for thermal dissipation.

Using the sensor

This sensor has five required connections: the input current (IP+ and IP-), logic power (VDD and GND), and the sensor output (VOUT).

The sensor requires a supply voltage of 4.5 V to 5.5 V to be connected across the VDD and GND pads, which are labeled on the bottom silkscreen. The sensor outputs an analog voltage on VOUT that is centered at 2.5 V and changes by 13.3 mV per amp of input current, with positive current increasing the output voltage and negative current decreasing the output voltage:

- VOUT=2.5V+0.0133VA⋅IP

- IP=VOUT–2.5V0.0133VA=(VOUT–2.5V)⋅75AV

The output is not ratiometric, so the zero point and sensitivity are independent of the actual supply voltage.

Setting the overcurrent fault threshold

The optional VOC pin can be used to set the overcurrent fault threshold. An on-board 205 kΩ resistor between VOC and GND sets the default overcurrent fault threshold to approximately 200% of the nominal sensing range, and an external resistor can be added in parallel between VOC and GND to lower this threshold to between 50% and 200%. The following equation gives the value of this parallel resistor, ROC, in kΩ as a function of overcurrent fault threshold percentage P:

- ROC=205kΩ⋅P205%–P

So for example, to set the overcurrent fault limit to 50% of the nominal sensing range, a 66 kΩ external resistor can be added between VOC and GND:

- ROC=205kΩ⋅50%205%–50%≈66kΩ

As a shortcut, VOC can be connected directly to ground to set the overcurrent fault limit to 100% of the nominal sensing range.

Alternatively, the on-board resistor can be replaced, or a low-impedance voltage source can be applied directly to the VOC pin as described in the ACS37220 datasheet.

The optional FAULT pin is normally at VDD and is pulled low when the IP current magnitude exceeds the set overcurrent fault threshold in either direction. This pin only asserts while the fault condition is present (it is not latched).

We manufacture these boards in-house at our Las Vegas facility, which gives us the flexibility to make these current sensors with custom default overcurrent fault thresholds. If you are interested in customization, please contact us.

Making connections to the board

You can insert the board into your current path in a variety of ways. The largest through-holes are 6.4 mm in diameter with 22 mm spacing. These can be used with #12 or M6 screws for attaching various types of lugs or solderless ring terminals, or thick wires up to 4 AWG can be soldered directly to the board. The slots near the edge of the board can accommodate a 4-pin terminal block or other connector with a pitch between 7.5 mm and 9.5 mm. Examples of these kinds of connections are shown in the pictures below. Holes with 0.1″, 3.5 mm, and 5 mm spacing are also available for connecting male header pins or terminal blocks, but please note that these smaller connection options are generally not suitable for high currents like those this sensor is intended for.

Warning: This product is intended for use below 30 V. Working with higher voltages can be extremely dangerous and should only be attempted by qualified individuals with appropriate equipment and experience.

Documentations:

- The dimension diagram is available as a downloadable PDF (400k pdf).

- ACS37220 datasheet

Package Includes:

- 1 x Pololu 5295 / 5297 ACS37220LEZATR-100B3/100B5 Current Sensor Large Carrier -100A to +100A, 3.3V / 5V

Pololu 5296 / 5298 ACS37220LEZATR-150B3/150B5 Current Sensor Large Carrier -150A to +150A, 3.3V / 5V

- Brand: Pololu

- Product Code: Pololu-5296-5298-ACS37220LEZATR

- Reward Points: 7

- Availability: In Stock

- रo 707.00

-

रo 679.00

- Price in reward points: 707

-

- 20 or more रo 702.00

- 25 or more रo 676.00

- 100 or more रo 640.00

Available Options

Related Products

Pololu 5290 / 5292 ACS37220LEZATR-100B3/100B5 Current Sensor Compact Carrier -100A to +100A, 3.3V / 5V

This is the compact version of a simple carrier for Allegro’s ACS37220LEZATR-100B3/100B5 Hall effect..

रo 451.00 रo 470.00

Pololu 5295 / 5297 ACS37220LEZATR-100B3/100B5 Current Sensor Large Carrier -100A to +100A, 3.3V / 5V

This is the large version of a simple carrier for Allegro’s ACS37220LEZATR-100B3/100B5 Hall effect-b..

रo 679.00 रo 707.00

Tags: Pololu, ACS37220LEZATR, 150B3, 150B5, Current Sensor, 3.3V, 5V